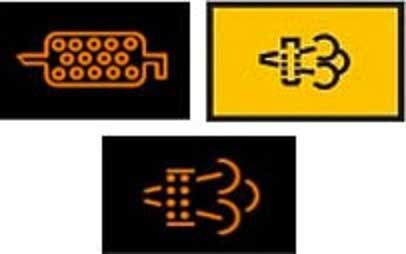

What is a DPF (Diesel Particulate Filter)

What is a Diesal Particulate Filter (DPF)? A Diesel Particulate Filter, often referred to as the DPF is a filter designed and integrated into the exhaust system to trap & remove Diesel Particulate Matter or Soot from the exhaust gasses of the diesel engine. Much like the Catalytic…